The Importance of Electrical Installation Testing to Ensure Safety

Electrical inspection and testing is an essential part of ensuring the safety and reliability of electrical installations. The process involves a thorough examination of electrical installations, equipment, and appliances, followed by testing to determine their safety and compliance with relevant regulations and standards.

Who Oversees The Process

In the UK, electrical inspections and testing are regulated by the Health and Safety Executive (HSE) and the Institution of Engineering and Technology (IET). These organisations set the guidelines and standards that must be followed to ensure that electrical installations and equipment are safe and fit for purpose.

Who Does the Inspection

Electrical inspections are carried out by qualified electricians who have received specialised training in inspection and testing techniques. These professionals are known as electrical inspectors, and they have the expertise to identify potential hazards and faults in electrical systems and equipment.

Visual Examination

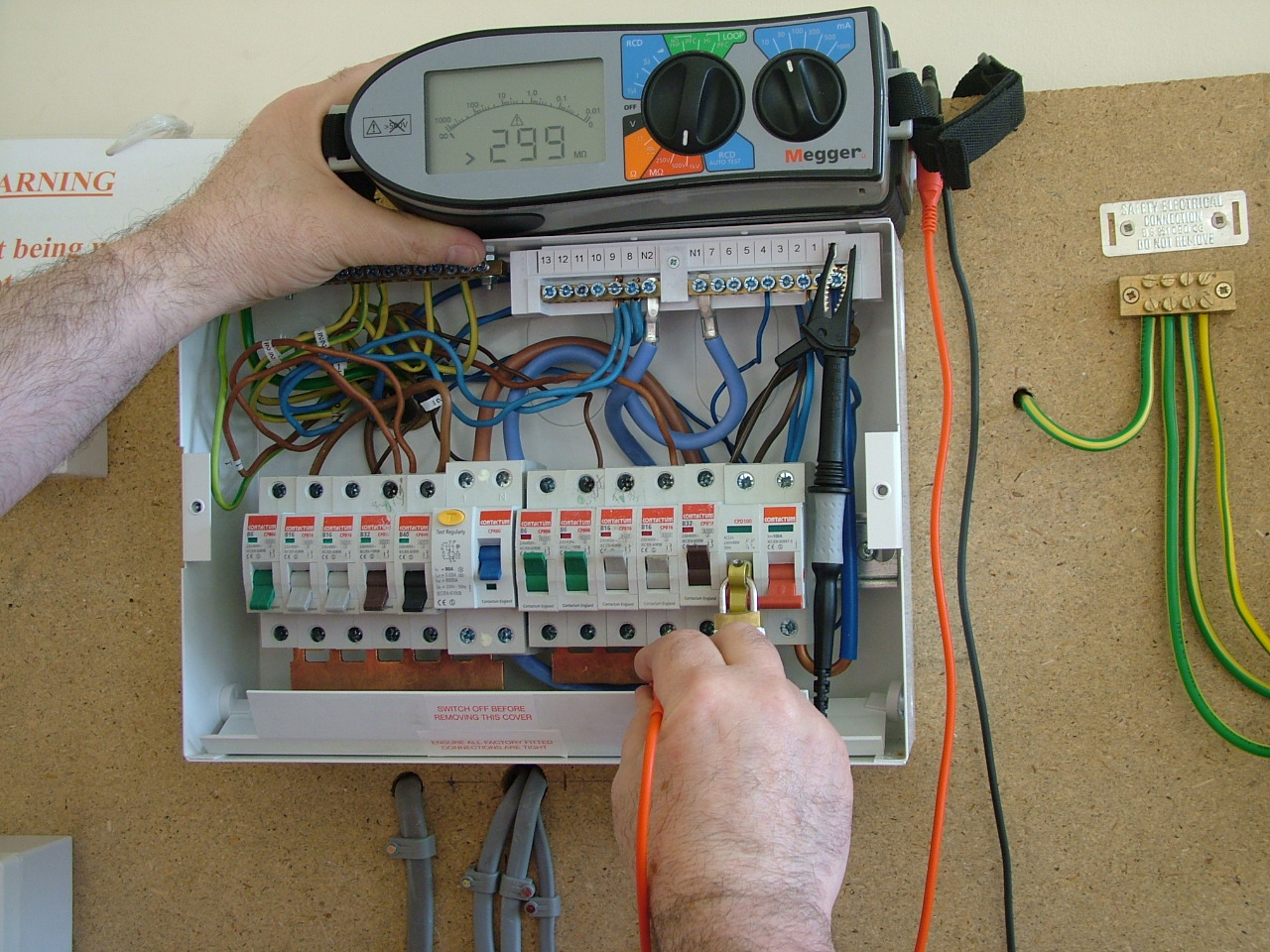

The process of electrical inspection involves a visual examination of electrical installations and equipment, followed by a series of tests to assess their safety and performance. The visual examination involves a thorough inspection of all visible electrical components, including wiring, switches, sockets, and electrical panels.

During this process, the inspector will look for signs of wear and tear, damage, and other issues that may pose a hazard. They will also check to ensure that all components are properly grounded, and that there are no exposed wires or other potential hazards.

Once the visual inspection is complete, the inspector will move on to testing. This involves using specialised equipment to measure the electrical current, voltage, and other parameters of the electrical system or equipment being tested.

Testing Process

There are several types of tests that may be performed during an electrical inspection, including insulation resistance testing, earth continuity testing, and polarity testing. Each of these tests is designed to assess a different aspect of the electrical system or equipment being tested.

Insulation resistance testing is used to measure the resistance of the insulation material that surrounds electrical conductors. This test is important because damaged or deteriorated insulation can lead to electrical faults and potential hazards.

Earth continuity testing is used to ensure that there is a good connection between the electrical system and the earth. This is important because a faulty or missing earth connection can increase the risk of electrical shock or fire.

Polarity testing is used to check the correct wiring of electrical systems and equipment. This test ensures that the live and neutral wires are properly connected and that there is no risk of electric shock or fire.

Completion of Test

Once the testing is complete, the inspector will provide a detailed report of their findings. This report will highlight any issues or hazards that were identified during the inspection and testing process and provide recommendations for addressing them.

What You Need To Do

If any issues or hazards are identified, it is the responsibility of the property owner or manager to take appropriate action to rectify them. Failure to do so can result in serious consequences, including fines, legal action, and even injury or death.

In addition to periodic inspections and testing, it is also important to ensure that electrical systems and equipment are properly maintained and serviced. This can help to prevent faults and hazards from developing over time, and can extend the lifespan of electrical components and equipment.

Overall, electrical inspection and testing is a critical part of maintaining the safety and reliability of electrical systems and equipment in the UK. By ensuring that electrical installations and equipment are properly inspected, tested, and maintained, property owners and managers can help to prevent hazards and ensure the safety of their occupants and employees.

PRW Electrical Services are qualified and registered electrical testing engineers. If you need a test carried out on your property, don't hesitate to call us.

via PRW Electrical Services ift.tt/pX85IwA